Contribute to the world with high quality technologies and abundant experiences.

NAGAOKA SCREEN INTERNALS

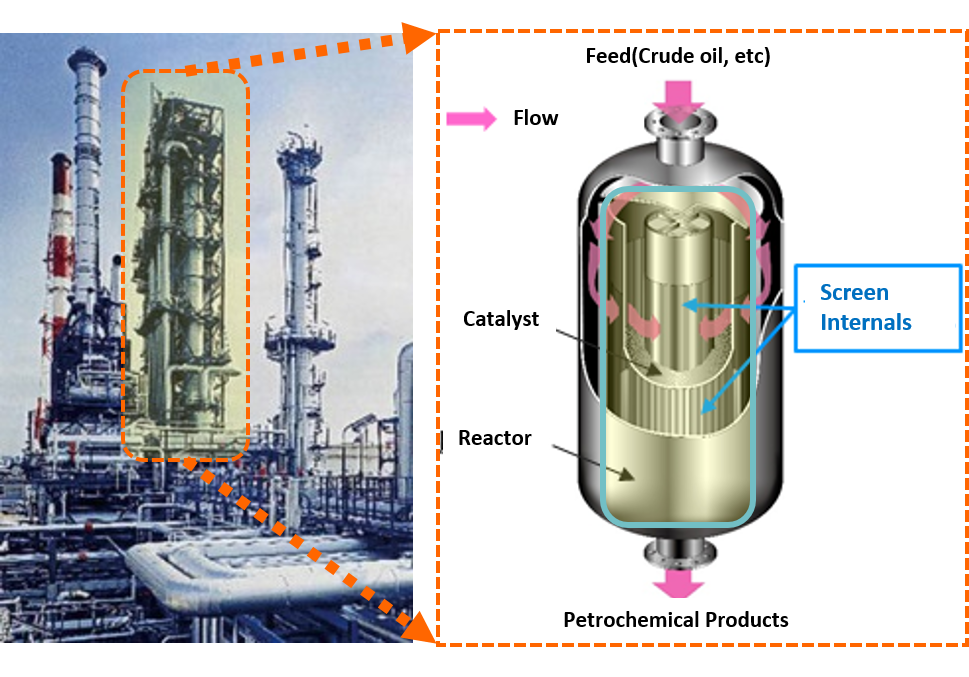

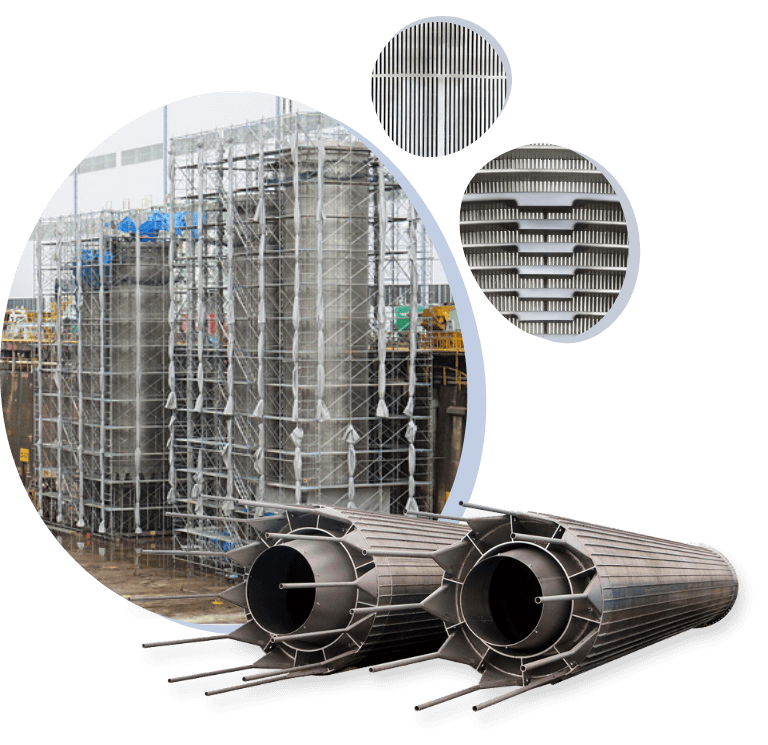

Nagaoka Screen Internals are used in the heart of oil refining, petrochemical and chemical fertilizer complex.

Screen Internals are operated under high temperature, pressure and corrosive environment,

hence requiring high strength and precise design, which can only be achieved with high technology and cultivated experience.

The products made from the production process are essential to our daily life.

BUSINESS LINE

Products and Process of Chemical Raw Materials Created in a Plant.

Oil Refining and Chemical Plant

Fuel and Chemical Fiber, necessary component for a daily life.

NAGAOKA SCREEN INTERNALS are used in the worldwide as internal equipment of reactor that is the heart of oil refining and chemical plants, and are one of the few companies approved for the manufacturing of Screen Internals around the world.

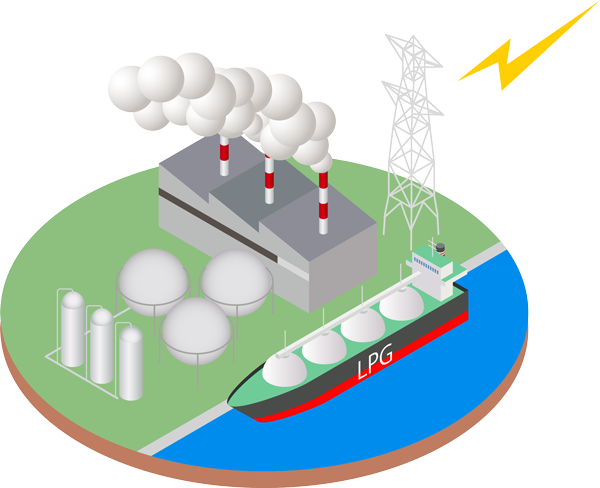

Introduce the process of NAGAOKA SCREEN INTERNALS with using propane gas.

Propane Gas (LPG)

Screen Internals (Inside portion of Reactors)

Reactor; the Heart of the Plants

Hydrogen (By Products)

Polypropylene

Propylene

Medical Equipment (Syringe etc.)

Home appliances

Vehicles (Bumpers, Battery Containers, etc.)

Utilized as fuel in plant, and recognized as new energy.

FEATURES

Internals for Reforming Reactors

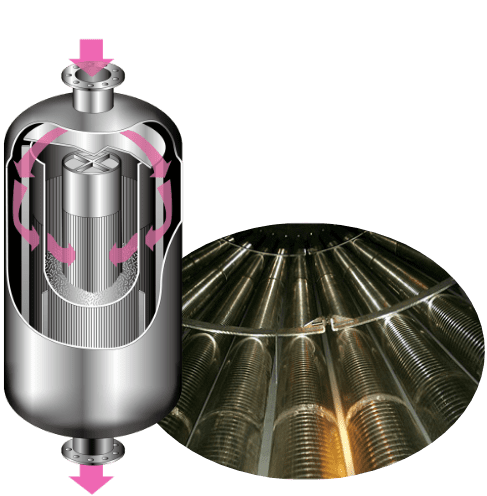

The reactors for the reforming units with continuous regeneration are one of the reactors in the oil refining and petrochemical processes, in which activated catalysts are sent to subsequent processing equipment for regeneration. Both these reactors and regenerators are “Radial Flow type” consisting of inner and outer catalyst support baskets, for which the NAGAOKA SCREEN BASKET is recommended by the leading process owners as the most suitable internals for process efficiency.

NAGAOKA SCREEN facilitates smooth catalyst movement without clogging and less damage to the catalyst due to the continuous vertical slots and smooth surface.

PRODUCTS

-

INTERNALS for RADIAL FLOW REACTOR

NAGAOKA SCREEN INTERNALS have perfect feature for the catalyst support on radial flow type reactors during refining and petro-chemical processes. NAGAOKA SCREEN INTERNALS offer high performance under severely high temperature due to its durable structure.

-

INTERNALS for Down Flow Reactors

For down flow type reactors, NAGAOKA SCREEN INTERNALS are used not only for catalyst support, but also for molecular sieve support, ion exchange resin support and other applications. NAGAOKA SCREEN bed support is widely used at the variety of process in refining, and petro-chemical industries.

Since the bed support must be capable of withstanding significant catalyst load and drop in pressure, a strong structure is required for the support.

NAGAOKA strives to be involved from initial stage of the design for our customer and process owner, optimizing the production and contributing to reliability of the process.

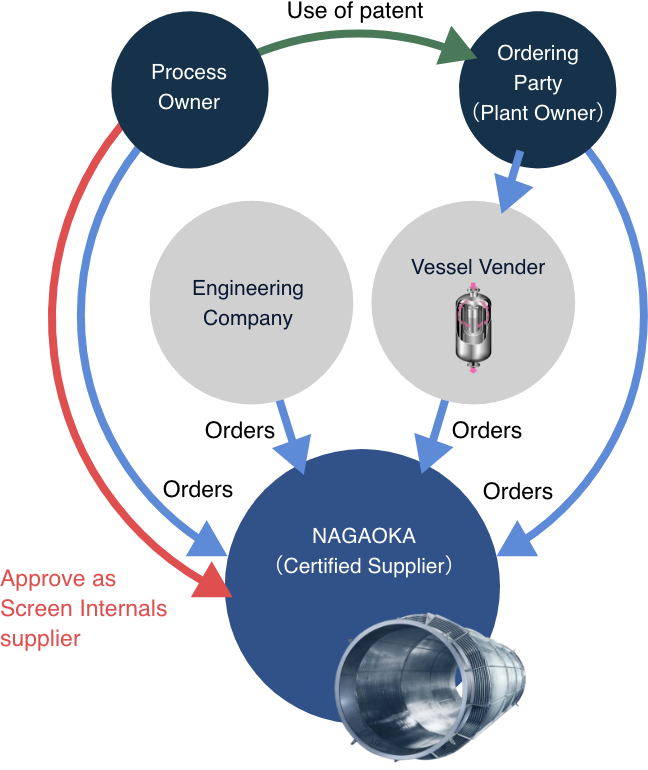

QUALIFIED SUPPLIER

-

One of the Few Qualified Supplier for Screen Internals Supply over the World, the Only One in Japan.

Internals are one of the most critical component in oil refining process. Only three companies are approved by Process Licensors (UOP and IFP / Axens, etc.) for the manufacturing of Screen Internals around the world. Few suppliers in the world and NAGAOKA in Japan.The Process Licensors issue license of patents and basic design of oil refining and petrochemical complex to Plant owners. The use of “Certified” Screen Internals manufacture are the necessary condition for performance guarantee of oil refining and petrochemical complex by the Process Licensors.

-

Approved by Process Licensors

IFP / Axens (Axens) in 1976

UOP LLC (Honeywell UOP) in 1978

Dow Chemical in 1978

Badger / CB&I (Lummus Technology) in 1981

Kellog (KBR) in 1990

Haldor Topsoe in 1991

Shell,Chevron in 2006

Haldor Topsoe (Requalified) in 2009

TECHNOLOGY &ACHIEVEMENTS

-

Cooperative Development with UOP LLC

In 1990, NAGAOKA has made a collaborative technology development agreement with leading process licensor UOP, since then NAGAOKA has contributed to development of internals in various process. Additionally, NAGAOKA has succeeded in co-developed Profile Wire Scallop with UOP in 1999.

-

Engineering agreement in 1990

-

Development of New Profile Wire Scallop in 1999

Technical Service

NAGAOKA provides technical service for on-site inspection, installation, maintenance and replacement at turn around in pursuit of customer satisfaction.

-

-

Delivery record

- 1.Adsorbent Chamber (Manufacturing materials for chemical fiber, plastic bottles, etc.)

- 2.OleflexTM Units (Manufacturing materials for chemical fibers, tires, etc.)

- 3.Styrene Monomers (Manufacturing materials for resins, plastic, etc.)

- 4.Reformers・Regenerators (Manufacturing materials for high-octane fuel)

- 5.Ammonia Converter (Manufacturing materials for chemical fertilizer)

-

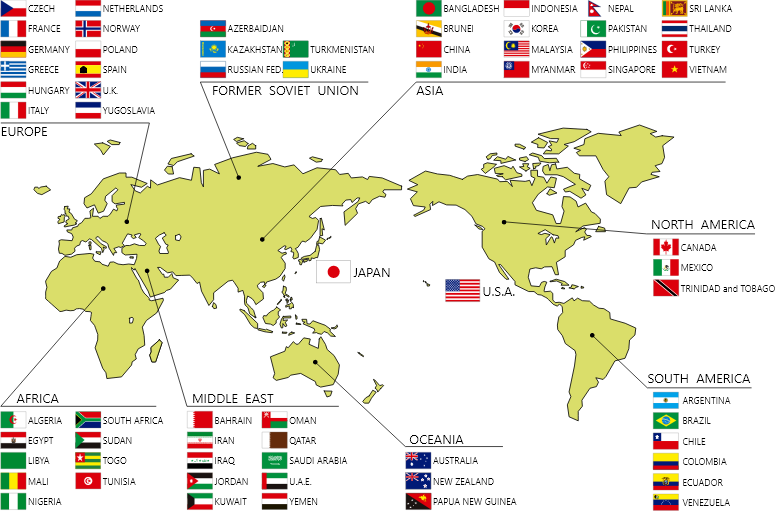

Supplied 65 countries worldwide, and continuously striving to develop new process unit

NAGAOKA SCREEN INTERNALS play a pivotal role in chemical reaction, extraction and separation in oil refining, petrochemical and chemical fertilizer plants. NAGAOKA SCREEN INTERNALS are supplied to 65 countries around the globe, and are operated successfully. High quality of NAGAOKA Products are acclaimed by many process owners globally, and agreed to cooperate for mutual development of new process. Hence, NAGAOKA has great potential and opportunities to expand.