WHAT IS NAGAOKA SCREEN?

-

NAGAOKA SCREEN INTERNALS FOR REFINING AND PETRO-CHEMICAL PROCESSING

- ■ ADSORBENT CHAMBER INTERNALS

- ■ CATALYST BASKET

- ■ CATALYST SUPPORT BED

- ■ CENTER PIPE

- ■ SCALLOPS

- ■ DISTRIBUTOR

- ■ DISTRIBUTOR BASKET

- ■ LIQUID DISTRIBUTOR TRAY

- ■ COLLECTOR

-

NAGAOKA WELL SCREEN FOR UNDERGROUND WATER COLLECTOR

- ■ RING BASE SCREEN

- ■ RING BASE COLLECTOR SCREEN

- ■ RING BASE RADIAL SCREEN

- ■ RING BASE INFILTRATION SCREEN

- ■ WATER INTAKE SCREEN

- ■ ROD BASE SCREEN

- ■ CERA-COAT SCREEN

- ■ PIPE BASE SCREEN

FEATURES OF THE NAGAOKA SCREEN

-

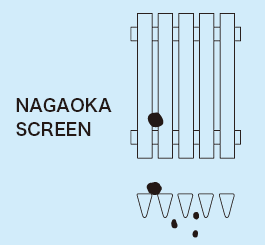

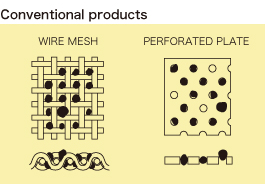

1. Clog-prevention Structure

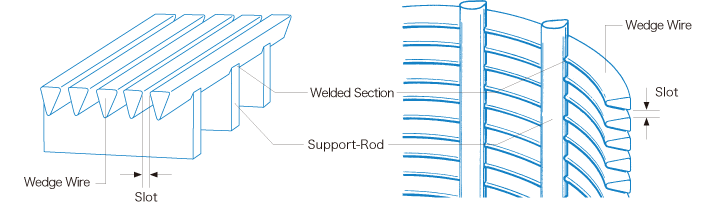

NAGAOKA SCREEN, made out of triangular-shaped wedge wires and supporting rods, allows the gas and the liquid flow in the reactors smooth and efficient.

-

2. High Slot Opening Ratio

Adjustable slot size offers high slot opening ratio compared with that of the conventional wire mesh and the slit pipes.

High opening ratio encourages the higher efficiency in process and less clogging in the oil refineries, petrochemical plants and water intake (in case of water wells.) -

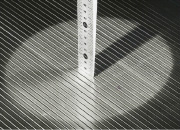

3. Rigid and Precise Welding and Uniform Structure

NAGAOKA offers unique continuous welding technology, ERW, which gives strength and accuracy in our products.

-

4. Multi-variation Shape and Material

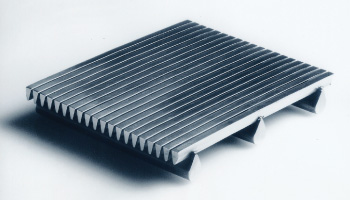

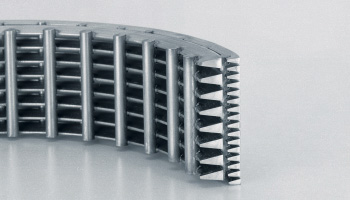

NAGAOKA produces a variety of screens ranging from a cylindrical- shape screen to a flat panel. NAGAOKA SCREEN, with reinforcement stiffeners and/or material alteration, offers high resistance to severe temperature and pressure.

NAGAOKA’S QUALITY ASSURANCE

-

Standard Quality Control

All NAGAOKA’s products are designed, manufactured, inspected and shipped in accordance with the ISO9001/2008 quality management system.

-

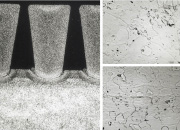

Welding Quality

The NAGAOKA SCREEN (Wedge Wire and Support Rod) welded by ERW (Electric Resistance Welding) has sufficient strength to satisfy various customer requirements. The performance of the welded parts has been analyzed and proven by macro, microphotographs and tensile strength tests.

-

Material Inspection by PMI

PMI (Positive Material Identification) is performed to ensure the chemical composition of alloy materials confirming to the job requirement for materials used in the reactor internals.

-

Screen Slot

The slot of the NAGAOKA SCREEN is well controlled to ensure accuracy by filler gauge and taper gauge.

Milestones of Technological Development of NAGAOKA

-

Nagaoka ScreenCore-Technology

Developed in 1972

- ●Enough strength to resist high temperature, high pressure and corrosion-prone condition.

- ●Clog-prevention structure

- ●High slot opening ratio

- ●Durable design and material

-

Screen Internal

First introduced in 1975

●Foundation of manufacturing technology for screen basket

-

Screen for water intake

First introduced in 1980Application of sand control technology

-

Infiltration gallery

Infiltration gallery

-

Shallow well

Shallow well

-

-

HiSIS High-speed Seabed Infiltration System

Application of river-bed water intake technology to seawater intake

First pilot plant started in 2014

- ●Seawater intake using seabed sand filtration

- ●High-effective purification system without does of chemicals for seawater

- ●Original sand control technology

CHEMILESExtremely High Speed Chemical-less Groundwater Treatment System

Remove harmful substance such as iron, manganese, ammonium nitrogen contained in groundwater

Developed in 1997- ●Original sand control technology

- ●Completely remove harmful substance by contact oxidation and biological treatment

- ●Extremely high speed water treatment system